In the complex machinery of an automobile engine, every component plays a vital role in ensuring smooth operation and longevity. Among these components, rod bearings are essential in connecting the crankshaft to the pistons, allowing them to function effectively within the engine’s assembly. Understanding what rod bearings are, their significance, and the potential issues that can arise from their failure is crucial for any vehicle owner or enthusiast. In this comprehensive guide, we will explore the function of rod bearings, common causes of failure, symptoms to watch out for, and how to address these issues effectively.

What Are Rod Bearings?

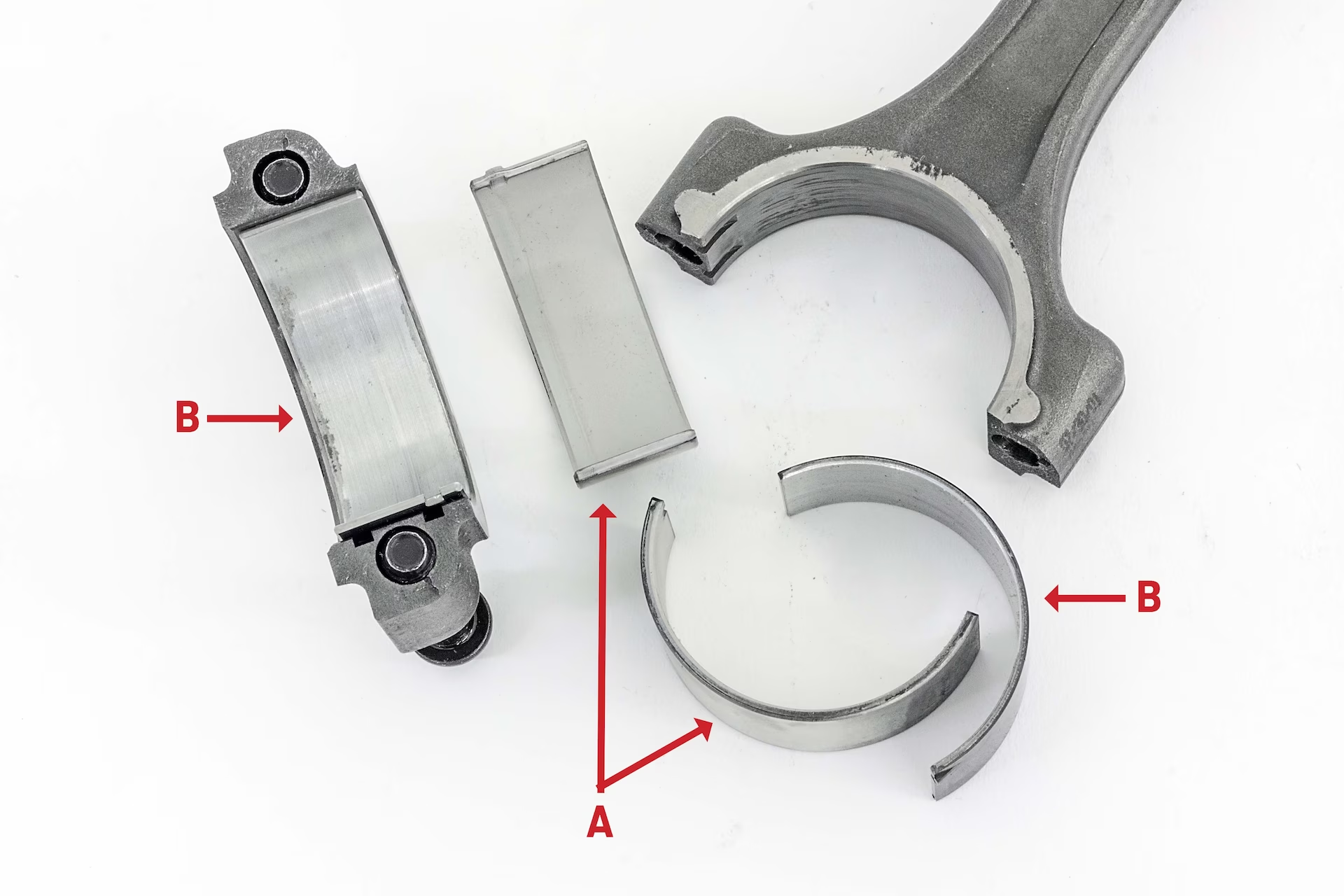

Rod bearings, also known as connecting rod bearings, are critical components of an internal combustion engine. They serve as a bridge between the connecting rods, which are attached to the pistons, and the crankshaft. These bearings allow for smooth rotation of the crankshaft while also enabling the connecting rods to pivot as the pistons move up and down within the cylinders.

Rod bearings are typically made of a durable material, often a metal alloy with a coating designed to reduce friction and wear. Their design allows them to withstand significant stress and heat generated during engine operation. Properly functioning rod bearings contribute to the overall efficiency of the engine, affecting performance, fuel economy, and longevity.

How Do Rod Bearings Work?

The primary function of rod bearings is to support the rotating crankshaft and allow for the transfer of power from the pistons to the crankshaft. As the engine operates, the pistons move up and down in the cylinders, causing the connecting rods to pivot at the crankshaft. The rod bearings facilitate this movement by providing a smooth surface for the crankshaft to rotate against.

The bearings are lubricated by engine oil, which helps to reduce friction and dissipate heat. This lubrication is vital for maintaining the integrity of the rod bearings and ensuring they function correctly over time. However, if the lubrication fails or is compromised, it can lead to significant problems within the engine.

Common Causes of Rod Bearing Failure

Rod bearing failure can occur due to various factors, often stemming from poor maintenance, operational issues, or material defects. Understanding these causes can help vehicle owners take preventive measures to protect their engines. Here are some common causes of rod bearing failure:

- Lack of Proper Lubrication: Insufficient oil supply or dirty oil can lead to inadequate lubrication of the rod bearings. When oil fails to circulate properly, friction increases, causing wear and overheating.

- Overheating: Excessive engine temperatures can damage rod bearings. Overheating may result from coolant system failures, blocked coolant passages, or a malfunctioning thermostat.

- Poor Engine Design: Some engines may have inherent design flaws that contribute to rod bearing failure. These may include inadequate oiling systems or poor bearing material quality.

- Low Oil Pressure: Low oil pressure can indicate underlying issues within the engine, such as worn oil pumps or clogged oil passages. Insufficient pressure can lead to inadequate lubrication of the bearings.

- Excessive Engine Load: Operating the engine under excessive load can strain the rod bearings. This can occur in situations such as towing heavy loads or aggressive driving.

- Contamination: Dirt, debris, and metal particles in the engine oil can damage the rod bearings. Regular oil changes and maintenance can help mitigate this risk.

- Improper Installation: Incorrectly installed rod bearings can lead to premature wear and failure. It is essential to follow manufacturer specifications during installation to ensure proper fit and function.

Symptoms of Rod Bearing Failure

Recognizing the symptoms of rod bearing failure early can be crucial in preventing further damage to the engine. If you experience any of the following signs, it is essential to investigate promptly:

- Knocking Noise: One of the most common symptoms of rod bearing failure is a knocking or tapping noise coming from the engine. This sound typically occurs during acceleration and may worsen as the engine revs higher.

- Loss of Power: A noticeable decrease in engine power and responsiveness can indicate rod bearing issues. The engine may struggle to accelerate, or you may experience a decrease in overall performance.

- Oil Pressure Warning Light: If the oil pressure warning light illuminates on your dashboard, it may signal low oil pressure, which can lead to rod bearing failure.

- Metal Shavings in Oil: During an oil change, if you notice metallic particles or shavings in the oil, it could indicate that the rod bearings are wearing down and may be on the verge of failure.

- Excessive Oil Consumption: An increase in oil consumption may suggest that the engine is experiencing issues, potentially including rod bearing failure.

- Engine Overheating: If the engine temperature rises significantly, it may indicate that the rod bearings are not functioning correctly, leading to overheating.

Diagnosing Rod Bearing Issues

If you suspect that your vehicle may be experiencing rod bearing problems, it’s crucial to diagnose the issue promptly to prevent further damage. Here are some steps to take:

- Listen for Unusual Noises: Pay attention to any knocking or tapping sounds coming from the engine. If you hear unusual noises, it may be time to have the engine inspected.

- Check Oil Levels: Regularly monitor your engine oil levels. If the oil level is low, add oil as necessary, and consider scheduling an oil change if the oil appears dirty or contaminated.

- Monitor Oil Pressure: Use an oil pressure gauge to check the oil pressure. If the pressure is consistently low, it may indicate a problem with the oil pump or oil passages.

- Inspect the Oil: During an oil change, inspect the oil for metallic particles. If you notice shavings or metal flakes, it could indicate rod bearing wear.

- Consult a Professional Mechanic: If you suspect rod bearing issues, it is essential to consult a qualified mechanic. They can perform a thorough inspection and diagnose the problem accurately.

Repairing or Replacing Rod Bearings

If rod bearing failure is confirmed, addressing the issue quickly is essential to prevent further damage to the engine. The most common solutions include:

- Bearing Replacement: Replacing the worn rod bearings is often necessary to restore engine function. This process involves disassembling the engine and replacing the old bearings with new ones.

- Crankshaft Inspection: When replacing rod bearings, it’s essential to inspect the crankshaft for wear or damage. If the crankshaft is damaged, it may need to be resurfaced or replaced.

- Oil System Repair: If low oil pressure or inadequate lubrication is a contributing factor, addressing any underlying oil system issues is critical. This may involve repairing or replacing the oil pump, oil filter, or oil passages.

- Engine Rebuild: In severe cases of rod bearing failure, a complete engine rebuild may be necessary. This process involves replacing worn components and restoring the engine to optimal performance.

Preventing Rod Bearing Failure

Preventing rod bearing failure requires consistent maintenance and attention to detail. Here are some preventive measures vehicle owners can take:

- Regular Oil Changes: Adhere to the manufacturer’s recommended oil change intervals. Using high-quality oil and filters can help maintain proper lubrication and reduce contamination.

- Monitor Oil Levels: Regularly check oil levels and top off as needed. Low oil levels can lead to inadequate lubrication and increase the risk of rod bearing failure.

- Check Oil Pressure: Ensure that the oil pressure remains within the manufacturer’s specifications. Address any oil pressure issues promptly to avoid potential damage.

- Maintain Cooling System: Keep the engine cooling system in good condition to prevent overheating. Regularly check coolant levels, hoses, and the radiator for leaks or damage.

- Avoid Excessive Loads: Be mindful of the loads you place on your vehicle, especially when towing or carrying heavy loads. Excessive strain can put unnecessary stress on the engine and its components.

- Listen for Unusual Sounds: Pay attention to any unusual sounds coming from the engine. Early detection of issues can lead to quicker resolutions and prevent further damage.

- Use Quality Parts: When performing repairs or maintenance, always opt for high-quality replacement parts to ensure optimal performance and longevity.

Conclusion

Rod bearings are vital components of an engine, and understanding their function, potential failure causes, and symptoms is crucial for vehicle owners. Recognizing the signs of rod bearing failure and addressing issues promptly can save you from costly repairs and keep your engine running smoothly.

By prioritizing regular maintenance, monitoring oil levels, and being attentive to unusual sounds or performance issues, you can help prevent rod bearing failure and ensure the longevity of your engine. Whether you’re a car enthusiast or a casual driver, staying informed about the components that keep your vehicle running is essential for a safe and enjoyable driving experience.